Observations from My Sight Visit to the Barry-Wehmiller Papersystems (BWPS) Plant in Phillips, WI.

The owner, Bob Chapman, together with Raj Sisodia, wrote about his people-centered leadership philosophy in the acclaimed book, Everybody Matters! The Extraordinary Power of Caring for Your People Like Family. Conscious Capitalism Inc. arranged this sight visit for an intimate group 12 visitors – CEOs, presidents, founders, owners of private and public companies. As an experienced management consultant, I wanted to see, firsthand, how the Everybody Matters! philosophy had changed the plant’s culture and impacted the business. It did. In very positive ways.

Falling in love with Jeff.

At our arrival dinner, I was seated with Jeff Stilts, one of the front line team members at the Barry-Wehmiller Papersystems plant. Jeff and I had a lot in common. We both have small town backgrounds — fishing, making up our own games, the community feeling. Jeff asked and listened in a way that bridged any differences in our job levels, education, gender, or geography.

Jeff is talented and common sense smart. I asked him why he didn’t teach for the Barry-Wehmiller University, which is staffed by BW team members. He replied that he still had children at home and didn’t want to spend time away from them traveling. A rock-solid ethic for work-life balance was important to Jeff and BW respected that.

Jeff certainly would have been an outstanding instructor. What Jeff did not tell me about himself was that he had significantly influenced the culture and direction of the company. In 2002, Jeff was a member of the employee group that wrote the company’s Guiding Principles of Leadership (GPL). I felt that I had missed the chance to talk with him about how a group of employees came up with these ideas. It would have been like learning about the US Constitution from one of its writers. Darn your humility, Jeff.

As dessert was being served, we took turns introducing our partners to the larger group. I began by saying; “People will talk about us because I fell in love with Jeff tonight.” Yes, a funny factoid for a small town. But I was very impressed by Jeff’s innate skills. I wanted everyone to appreciate Jeff.

Visiting the plant.

Barry-Wehmiller Papersystems makes the machines that make different types of packaging. Each machine is custom-made. This factory is not an assembly line; it is an assemblage of craftspeople who work on the various parts that make up the customized machine. Sheet metal fabrication – Welding – Painting – Building electrical panels.

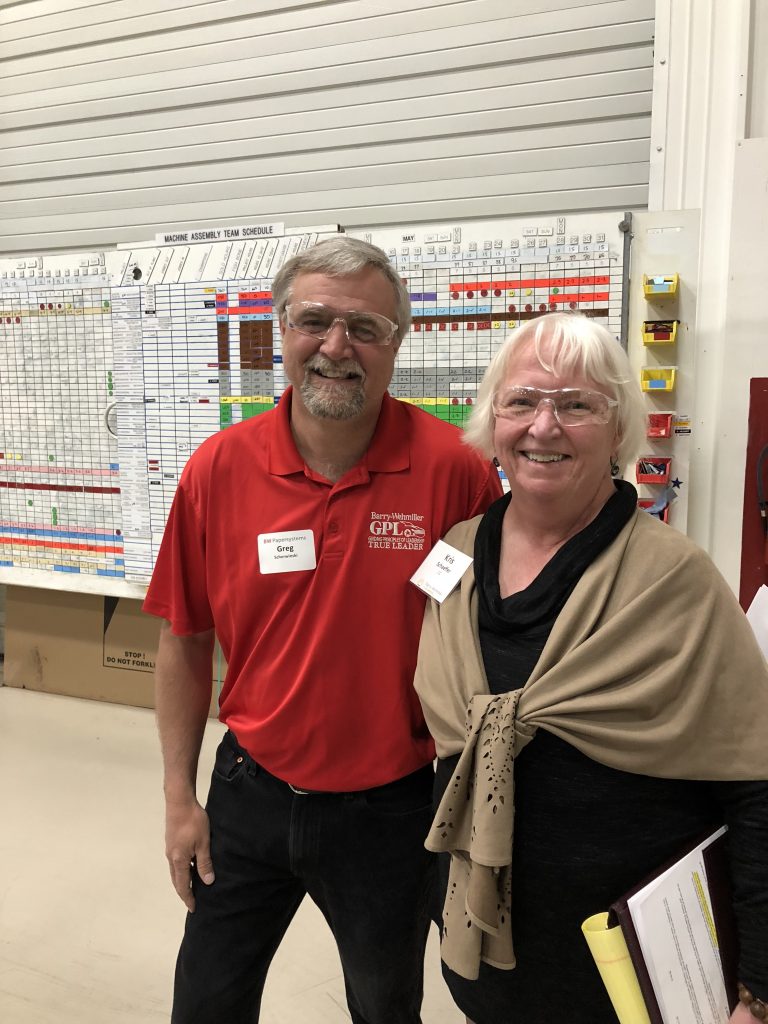

We got to the plant the next morning. As I checked in to get my hard-toed shoes and safety glasses, I was asked, “Are you Kris?” Jeff had already told them about our encounter. But this was not negative small town gossip. He had passed along a vibe that made me feel welcomed, accepted, and gladly anticipated. This is what I experienced with all the other BWPS team members – how well they treat guests and each other.

Now on the factory floor, I could see firsthand how this openhearted harmony worked. Dennis Lemke was our wise guide. Once an engineer and now a VP at the plant, Dennis could point out how this people-centered culture helped productivity. He told the story about the job sheets. A job sheet contains the exact directions to do a job task — the learnings, short-cuts, and cautions from the expert who has mastered the task. A job sheet would quickly guide someone to execute the task. But at one point, employees had not written many job sheets, for fear that someone could take their job.

The BW culture had turned this fear to trust during the 2009 economic downturn. The challenge — how could the business survive a 40% cut in contracts with not one lay off? BW implemented a self-directed share-the-pain solution. They designed furloughs that employees could schedule and barter. Once employees saw that no one was going to lose their job, there was no further reason for fear. As evidence of the wellspring of goodwill, today there are 17,000 job sheets. Now, when sales at one plant are slow, they are able to “flex” inside the building and serve their sister companies. The BW plants are a coordinated resource to each other. BW plants reduce the need for outside contracting and expense because they know how to do the work themselves.

Dennis described the morning Touch Meeting as another example of daily teamwork. Everyone gathers around the Operations Board. Their first business is not business. It’s a personal check in about birthdays, kids’ sports, trivia, and laughter. “It’s beautiful to hear how you feel.”

And then these craftspeople review the computer-generated daily work plan. Assignments are not finished without human input. Team members swap hours. “I need some help to get this done in 8 hours.” “I have a couple of hours I can give you.” And together they work out the demands of the day. That honest harmony leads Barry-Wehmiller team members to achieve their definition of happiness – “Meaningful work among people we care about.”

Another way that trust shaped the plant is in continuous improvement. Barry-Wehmiller uses every day to refine their systems. In the first four months of the year, there have been over 300 improvement suggestions. That’s an incredible number! At BWPS, lean manufacturing isn’t just using your head to problem-solve. It’s also using your heart to see how to wring out frustration from the system. Caring leads to better ideas or as one person said, “Giving a sh*t.” That prompted a major declaration from one of the participants. “We implemented Lean Manufacturing first. If I had to do it all over again, I would have started by building the culture.”

Using Recognition and Celebration.

In the plant, there is a prominent Recognition Board full of pictures of awards and parties. It seemed as sincere and spontaneous as a kitchen refrigerator with many photos of the kids’ recitals and graduations. Awards are freely given and very cherished. Most awards are from peer nominations. During one of the team member panels, Jennie Bruner told her personal story of becoming a “Customer Trust Leader” because many people encouraged her. “I learned that I had something to offer people.” It’s stunning to have your co-workers value you.

The plant is full of team members wearing their awards. Badges. Jackets. Pins. They introduce others to guests with this recognition – not what the person does but what they have achieved. Personhood over position –

“We give awards to people who achieve something that is important to our culture, not just to our bottom line.”

Barry-Wehmiller also recognizes and celebrates people simply to let them know they matter. There were pictures of parties – birthday parties, company anniversary parties. The factory has a very High Touch, Low Tech design.

Tracy Williams, who is on the front line of Customer Trust, was the first winner of the GPL prize – for exemplifying the Guiding Principles of Leadership. She came to talk to us wearing her red shirt. For her, it was an extraordinary award. Sometimes, she has to do an unpopular task. After the sale, if a customer’s machine is down, Tracy may have to take a completed, working part from a machine in progress and ship it to that customer so they can get their plant running. As she puts it, it’s better to have havoc with a BW production schedule than have a customer who is unable to work at all.

Talking about Culture and Leadership.

Now that we had seen that the people-centric culture worked, we had questions about how to achieve it. Fortunately, the sight visit gave us more exposure to BW team members, to Bob Chapman and to the other designers of the company’s culture.

Brian Wellinghoff kicked off the discussion. He had started as an engineer and moved on to be one of the BWU instructors. He explained Barry-Wehmiller’s concept of culture. There are four components — Compassion. Integrity. Consistency. Competence. Which element comes first? Most businesses would start with Competence. Barry-Wehmiller turns around the sequence. Compassion comes first. They believe that good people will give you good performance. He explained that we develop people from the inside out.

Dennis Lemke provided an example of how to apply this model. At the plant, Dennis used “responsible freedom” on Mike, a project estimator. His job is to cost out a bid for a multi-million dollar machine. Mike would spend 40 hours to price a machine yet it would take him only a few seconds to give an estimate. But he was afraid to be wrong about his estimate. Dennis said, “We instilled belief in himself so he could do a quick quote. This really supports our sales department.” This is one example of using trust to build performance.

Shayne Roberts, a former engineer now in charge of human resources, reinforced the idea of compassion over competence. He said, “We never terminate for performance. We do terminate for behavior issues such as absenteeism or acting inappropriately. If someone is not performing, it’s the leader’s job to help the team member get up to speed.”

Shayne continued, “Culture is a commitment. This shift in mindset requires patience. Leaders are expected to practice that “courageous patience” along with deep listening and authentic vulnerability.

Shayne explained that it took over six years to build culture at this plant. “We wanted to build a culture that would last. Now we have our culture in everything we do — Safety. Leadership. Documents (such as the Guiding Principles of Leadership). Barry Wehmiller University. Vision of Service. Wellness.

“Every business has performance measures. We also have a dashboard of people measures which each leader is responsible for – safety, wellness, recognition, retention, and training participation.”

All of us agreed that it would take consistent leadership to embed our own companies with this people-centric culture. We were committed to try, though somewhat uncertain as to what would be the best path. Together we developed some ideas: Have cultural dialogues. Look for people to believe and get them to come along. Realize that it’s a journey; don’t expect quick results. Convert your cultural aspirations into behavior. There can be multiple interpretations of words. Actions tend to have “pure meaning.”

Wrapping up the Sight Visit.

This sight visit was ably designed by Conscious Capitalism, Inc.’s Chief Strategy Officer, Amanda Kathryn Roman and Barry-Wehmiller Leadership Institute’s partner, Brian Wellinghoff. It was a skillful blend of large and small group interactions, panels, and the plant visit. The Barry-Wehmiller way is to allow visitors full, unrestricted access to team members. Nothing is scripted. Everything is real.

About the author, Kris Schaeffer.

During the sight visit, I had an inspiring one on one with Bob Chapman. “Bob, I flunked retirement twice.” Bob looked directly at me. “You retire when all you have is work. You don’t retire when your work is a calling.” What is a calling? Something good for the world; good for me; and ####. What is my calling? Helping business to be a force for good.

I have worked on organizational culture for forty years. “Every company has a culture, but few by design.” Culture is not a quick fix but rather a steady, iterative effort over time. We get there by using a combination of six “cultural levers” that create systemic, sustained organizational change.

Today, I work with Conscious Capitalists to convert their vision and values into operational practices. “Values are exhibited in behaviors.” We use this model for change: The organization inspects leadership, structure, and process; while the individual level looks at people, tasks, and rewards. When these levers are aligned toward the company’s values, the right actions occur. The Barry-Wehmiller sight visit confirmed this.